Worldwide Leaders in Technology and Application of

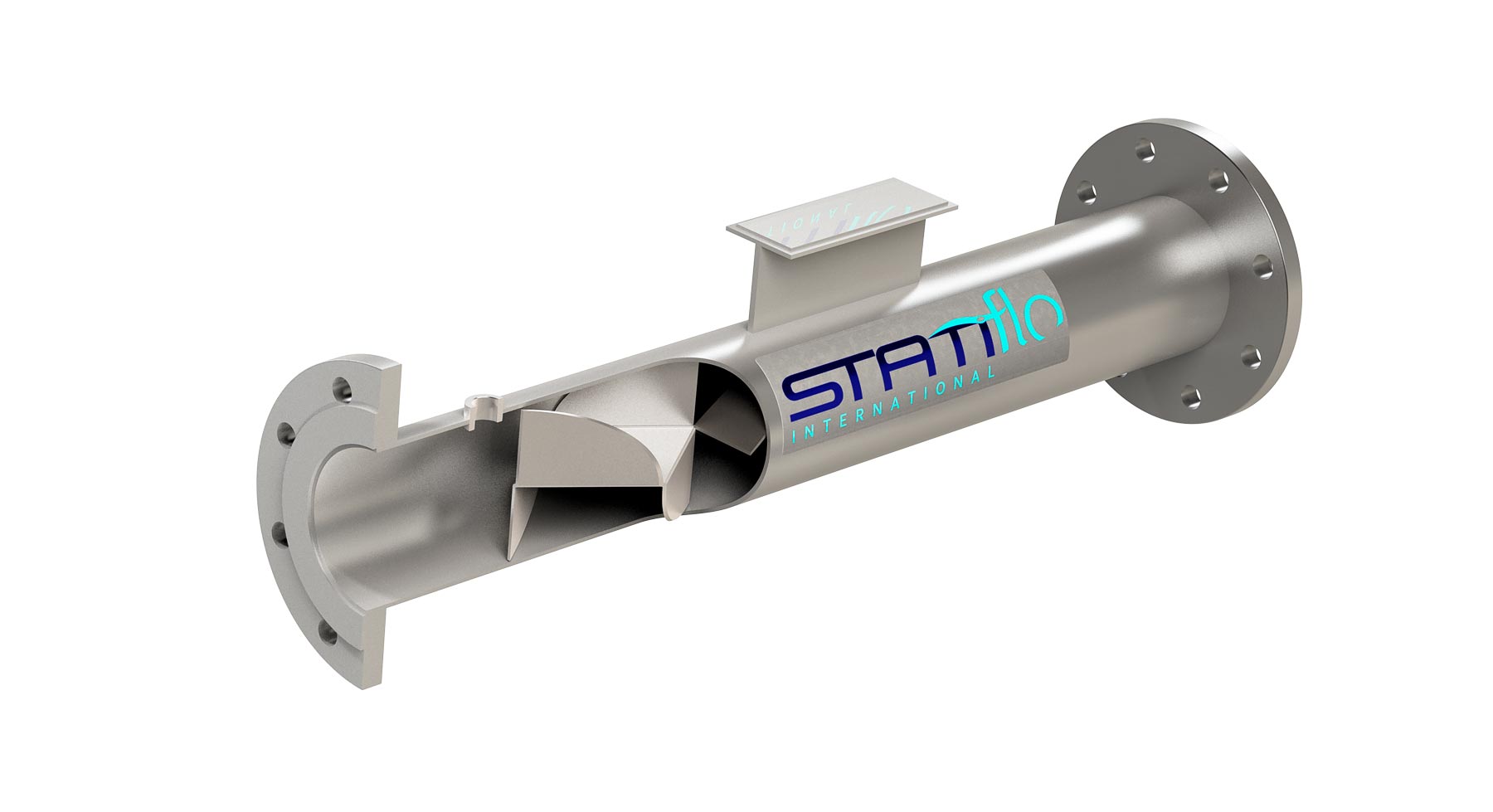

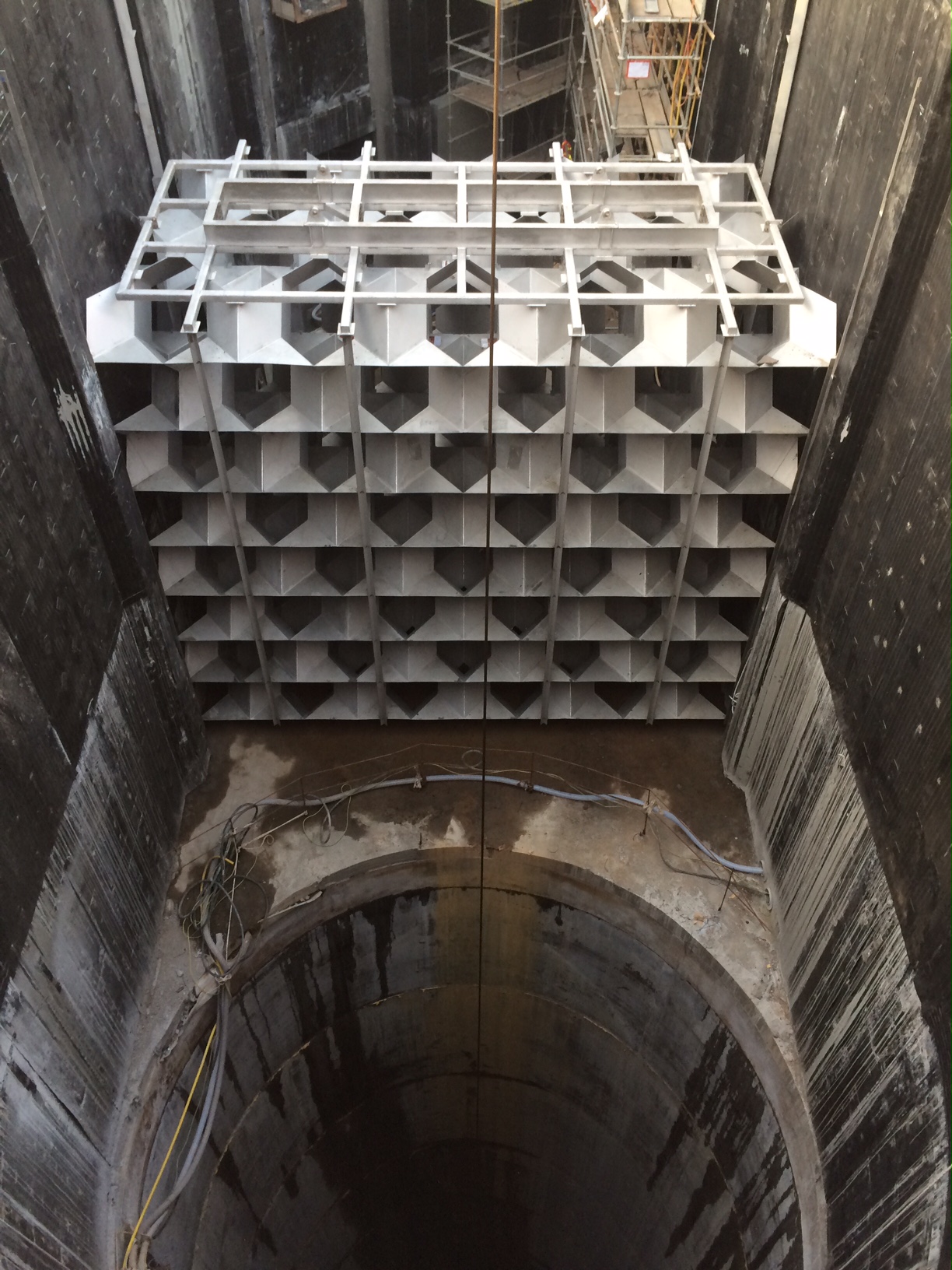

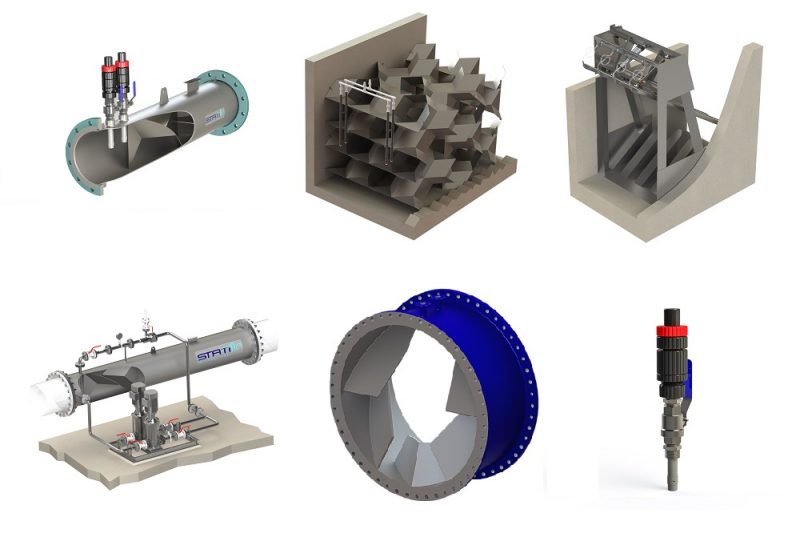

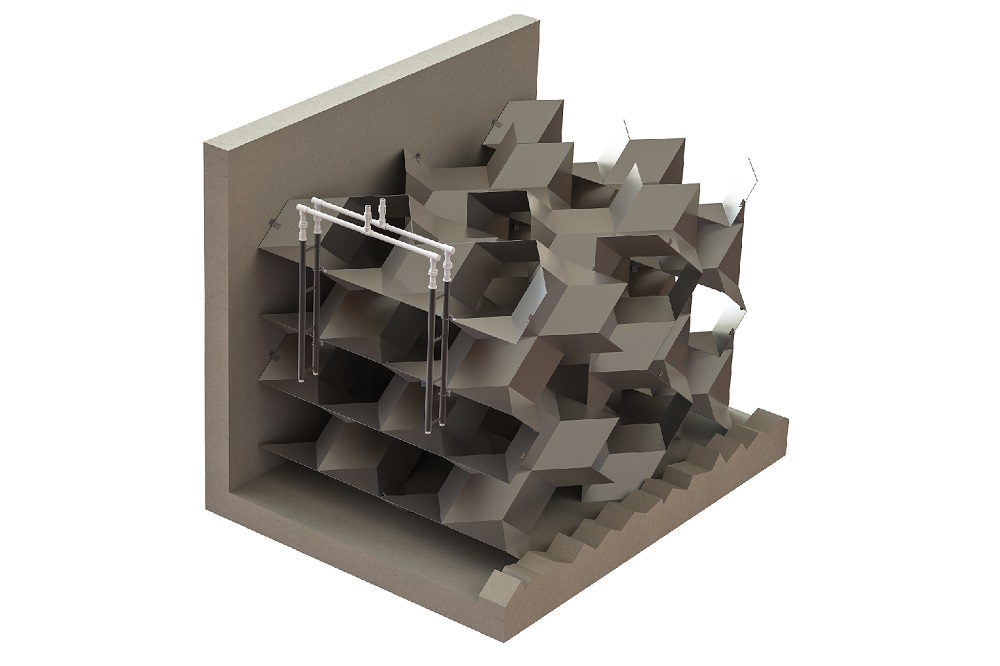

Static Pipe Mixers, Open Channel Mixers and Enclosed Duct Mixers

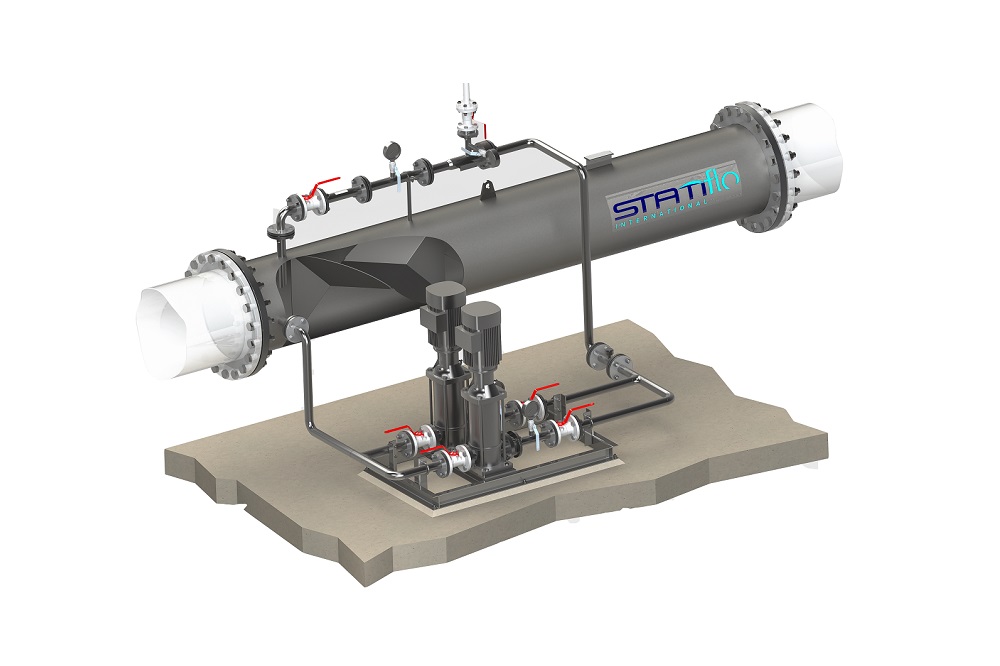

Statiflo is a world leader in the development and application of static pipe mixers, inline static mixers, channel mixers, duct mixers, gas dispersion systems and associated technologies with thousands of customers in every process industry in over 80 countries.

Our headquarters are located in Macclesfield, Cheshire, in the north west of England.

We also service industries throughout the world from offices strategically situated in the USA, Germany and Canada, as well as through our globally distributed network of business partners.

Through experience, innovation and inspiration Statiflo continues to strengthen its reputation as the world leaders in the design and manufacture of static mixers, channel mixers, gas dispersion systems and associated technologies.

Always mix with the right Company

Features and Benefits of Static Mixers

Highly efficient mixing results in low energy consumption – low pressure drop in pipes or low headloss in channels.

All Statiflo Static Mixers, for both pipes and channels, have been carefully designed to provide highly efficient mixing. Our range of products includes the most efficient designs currently available, as independently tested by BHR Ltd, in terms of the highest degree of mix in the shortest time and with the lowest energy consumption (pressure drop).

Unlike dynamic mixers, Statiflo Static Mixers have no moving parts and are virtually maintenance free.

No special skills are required other than normal engineering pipework skills.

Efficient mixing and high mixture quality reduces the consumption of dosed chemicals by eliminating the need to overdose to compensate for poor mixing.

Statiflo Static Mixers are both compact and efficient and, within reason, can be installed in the most restricted of spaces, including in bends in some cases.

Each Statiflo Static Mixer is carefully designed to meet the specific requirements of each application. For large installations, customer has the option to trade off OPEX with CAPEX – designs are available with low operating costs, but generally with high capital costs and vice versa.

Reduce time and distance between injection and sample allowing for rapid correction and adjusting of dose rate to improve product control and consistency.

Customers We Work With

Latest News

Static Mixers Vs Dynamic Mixers: Which Is Right For Your Process?

Static Mixers Vs Dynamic Mixers: Which Is Right For Your Process? In many industrial applications, including food processing, water and wastewater treatment, desalination, paper production, and general chemical processing, blending…

The Environmental Benefits Of Static Mixers In Wastewater Treatment

The Environmental Benefits Of Static Mixers In Wastewater Treatment Wastewater treatment plants play a critical role in protecting public health and the environment by treating and removing pollutants from wastewater…

Why Static Mixers Should Be Incorporated In The Aeration Process

Why Static Mixers Should Be Incorporated In The Aeration Process Aeration, the controlled process of introducing air into water, is critical in water treatment to promote the growth of beneficial…